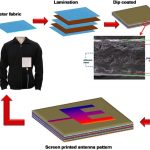

With the use of hybrid 3D printing, researchers are creating types of electronics that we’ve never seen before. Case in point, wearable electronics. A team of researchers at the Wyss Institute for Biologically Inspired Engineering at Harvard University have combined hard and soft electronic elements into durable and stretchable sensors. These sensors are a leap forward for creating completely flexible electronic goods.

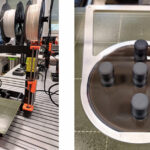

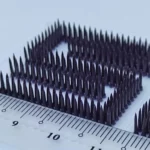

The researchers achieve this effect by first printing a stretchable conductive ink. After tuning the inks to their proper resistance, they then place electronic components at precise spots. The researchers then mount this arrangement onto a stretchable fabric.

This allows them to not only make electronics that operates whilst being flexible, but also reacts to elastic stress. The researchers made a machine that measures an amount of stress the fabric is under. It can achieve this because when the ink stretches it increases the ink’s resistance. They illustrated this by using the machine to measure the strain of bending one’s arm.

3D Printing Flexible Substrates For Soft Electronics

The researchers fabricated soft sensors using our hybrid 3D printing method, which allows stretchable conductive inks and soft matrices to be printed and integrated with surface mount electrical components, such as LEDs, resistors, and microprocessors.

The 3D printing material is made from TPU mixed with silver flakes. TPU is a natural fit for this project because of how flexible it is. During the print the silver flakes align themselves along the printing direction so that they overlap each other like plates. The TPU parts distribute the stress so that all of the solid parts adhere to the surface.

This arrangement allows the whole machine to be stretched by 30% and maintain all of its functions. Wearable electronics are somewhat of a holy grail many companies are chasing. The Air Force Research Laboratory Materials and Manufacturing Directorate and UES, the Vannevar Bush Faculty Fellowship Program under the Office of Naval Research, a generous donation from the GETTYLAB are all supporting the work and looking to implement it into their operations in the future.

“This new method is a great example of the type of cross-disciplinary collaborative work that distinguishes the Wyss Institute from many other research labs,” added Wyss Founding Director Don Ingber, M.D., Ph.D., who is also the Judah Folkman Professor of Vascular Biology at Harvard Medical School and the Vascular Biology Program at Boston Children’s Hospital, as well as a Professor of Bioengineering at Harvard SEAS. “By combining the physical precision of 3D printing with the digital programmability of electronic components, we are literally building the future.”

All images courtesy of Wyss Institute Harvard