As an additive manufacturing company owner or manager, you would have a vested interest in minimizing downtime on the factory floor. Machine downtime costs money, because your machines are your breadwinners. If the machines stop, for whatever reason, then it’s no more bread. It’s a simple equation.

Luckily, downtime in 3D printing businesses can be reduced, thanks to a combination of monitoring, tracking, and other management tools.

Causes of Downtime in the Factory

There are two significant causes of downtime in additive manufacturing facilities, which are process-related, and security related.

In the case of additive manufacturing process-related downtime, a lot of this can be put down to failed prints, particularly when the machine is running unattended overnight.

In the case of security-related downtime, security breaches can involve the theft or destruction of equipment, and in rare cases, even industrial espionage.

Thankfully, both of these issues can be addressed with a combination of surveillance technology and downtime monitoring software to ensure consistent operations. Pelco, for example, offers a range of industrial-grade surveillance cameras well suited to the factory floor.

Reducing Security-related Downtime

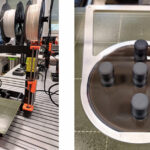

Cameras are a time-honored means of monitoring factories, and this still holds true for additive manufacturing businesses. Strategically located cameras can detect unusual activities, such as unauthorized access to restricted areas, tampering with machines, or theft of raw materials.

Cameras equipped with motion detection and facial recognition can monitor access points and ensure that only authorized personnel enter sensitive areas. Alerts can be triggered if a breach occurs, allowing immediate intervention to protect equipment and materials.

Advanced surveillance systems can also integrate with access control mechanisms, such as keycards or biometric readers, creating a layered security approach. If a door is forced open or an unauthorized entry is detected, the system can lock down the affected area, alert management, and log the incident for further investigation.

Reducing Downtime from Failed Prints

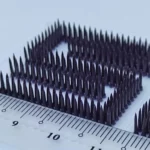

Failed prints are a common issue in 3D printing, but their impact can be mitigated with proper monitoring and response tools.

For workflow monitoring, high-definition cameras can visually monitor print progress. Cameras, especially when powered by AI / computer vision, can identify common issues, such as warping, layer shifts, or extrusion problems, and send alerts to operators when anomalies are detected. This enables operators to intervene early, reducing wasted material and time.

Downtime monitoring software can complement this by analyzing machine parameters, such as extrusion rates, bed leveling, and temperature consistency. If an issue arises, operators receive immediate notifications, allowing them to pause or adjust the print before further resources are wasted. This not only reduces downtime but also improves material efficiency.

Integrating Surveillance and Monitoring Systems

The integration of surveillance equipment with downtime monitoring software offers a unified solution for managing 3D printer performance. For instance, if a camera detects irregular filament movement during a print job, the monitoring software can cross-reference this with extrusion rate data to confirm a jam. Such integrated systems reduce reliance on manual inspections, streamlining operations and lowering labor costs.

Cloud-based platforms further enhance integration by enabling remote monitoring and control. Managers can view camera feeds, analyze machine performance, and implement corrective actions from anywhere with an internet connection. This level of oversight is particularly beneficial for facilities with multiple machines, such as large print farms.

Benefits of Implementing Surveillance

By deploying surveillance cameras in your 3D printing workplace, additive manufacturing facilities can achieve:

Enhanced Security: Reduced risk of theft, vandalism, and unauthorized access.

- Higher Efficiency: Early detection of print issues minimizes material waste and machine idleness.

- Improved Maintenance: Data-driven insights facilitate proactive maintenance, extending machine lifespans.

- Cost Savings: Reduced downtime directly translates to higher profitability and ROI.

- Ensuring safety standards: Monitoring activities with security cameras for manufacturing facilities can ensure proper machinery use.

In additive manufacturing, downtime often boils down to security breaches and failed prints. By incorporating surveillance cameras (and optional monitoring software), facilities can tackle these issues head-on, keeping operations smooth and profitability high.