The footwear industry generates significant waste, particularly from leather scraps, which are challenging to recycle due to adhesives, inks, and other contaminants. To address this issue, the ECOFAP project, spearheaded by AIMPLAS, Pikolinos, Evatalking, and the Footwear Technology Centre of La Rioja (CTCR), is developing a new 3D printing material derived from tanned leather waste. This innovation aims to create sustainable solutions for fashion, textiles, and footwear manufacturing while promoting circular economy practices.

The Valencian Community, responsible for producing 65% of Spain’s shoes—approximately 70 million pairs annually—generates an estimated 3,500 tonnes of leather scraps each year. Due to the complexity of the waste, traditional recycling techniques often result in low-quality materials or are entirely infeasible. Most of this waste ends up in landfills, contributing to environmental degradation.

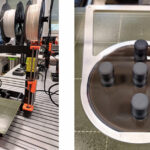

ECOFAP focuses on transforming this waste into a viable secondary raw material suitable for FDM 3D printing. By repurposing these scraps for shoe components like soles and heels, the project aims to reduce the industry’s carbon footprint and environmental impact.

New Technology for Micronized Leather

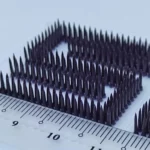

One of the key challenges tackled by the ECOFAP consortium is reducing leather waste into particles smaller than 10 microns. This micronization process is critical for enabling the material to blend effectively with polymers that possess the mechanical properties required for footwear applications.

The elasticity of collagen fibers in leather makes this task particularly demanding. However, the project’s goal is to combine micronized leather with suitable polymers to create a filament compatible with FDM 3D printing. This filament will be used to produce high-quality components for the footwear industry, such as soles and heels, while significantly reducing waste.

The ECOFAP initiative not only recycles waste but also creates a high-value product, allowing manufacturers to close the loop on material usage. This process exemplifies the principles of the circular economy by turning waste into a resource for new product development.

Funding and Collaboration

The ECOFAP project is funded by Spain’s Ministry of Science, Innovation, and Universities, with additional support from the European Union’s Next Generation funds. The collaborative effort between industry leaders and research institutions underscores the importance of innovative approaches to sustainability.

ECOFAP represents a major step forward in addressing the footwear industry’s waste problem. By combining 3D printing with recycled leather, the project showcases how innovative technologies can drive sustainability and reduce environmental impact. This initiative not only creates new possibilities for the industry but also sets an example for how circular economy principles can be effectively implemented.

Source: renewable-carbon.eu