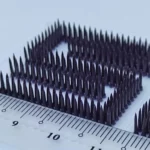

Researchers at University of Bristol have demonstrated a new sensing technology for quality control of parts in aerospace. Published in Waves in Random and Complex Media, the study outlines a formula guiding the design boundaries for component geometry and material microstructure.

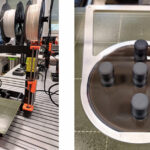

Unlike existing methods, this process employs non-contact ultrasonic array sensors, akin to those used in medical imaging.

The team developed a mathematical model, factoring in the physics of ultrasonic wave propagation through layered metallic materials produced via additive manufacturing. By adjusting input parameters, the model optimizes information output, crucial for assessing component mechanical integrity.

“There is a potential sensing method using a laser based ultrasonic array and we are using mathematical modeling to inform the design of this equipment ahead of its in situ deployment,” said Professor Anthony Mulholland, head of the School of Engineering Maths and Technology.

Anticipating accelerated industry adoption, Mulholland envisions collaborations to integrate the technology into additive manufacturing processes. This integration could lead to streamlined production, innovative designs, and bolstered economic competitiveness for UK manufacturing.

“Opening up 3D printing in the manufacture of safety critical components, such as those found in the aerospace industry, would provide significant commercial advantage to UK industry,” said Mullholland.

“The lack of a means of assessing the mechanical integrity of such components is the major blockage in taking this exciting opportunity forward. This study has built a mathematical model that simulates the use of a new laser based sensor, that could provide the solution to this problem, and this study will accelerate the sensor’s design and deployment.”

Moving forward, the team plans to assist experimental partners in deploying laser-based ultrasonic arrays. Robotic arms will deploy these sensors in controlled environments, generating detailed tomographic images for quality assessment. This advancement promises a transformative leap in additive manufacturing quality control.

You can read the full article titled “A probabilistic approach to modelling ultrasonic shear wave propagation in locally anisotropic heterogeneous media” at this link.

Source: bristol.ac.uk

Come and let us know your thoughts on our Facebook, X, and LinkedIn pages, and don’t forget to sign up for our weekly additive manufacturing newsletter to get all the latest stories delivered right to your inbox.