Researchers from the Department of Energy’s Oak Ridge National Laboratory (ORNL) have been honored with the 2023 Welding Journal Paper of the Year Award by the American Welding Society. The team’s work on repairing high-performance jet engine components using additive manufacturing earned them the prestigious Warren F. Savage Memorial Award, presented during the 2024 FABTECH show in Orlando, Florida.

The award-winning research team included former ORNL material scientist Niyanth Sridharan, now at Lincoln Electric India, ORNL computational material scientist Yousub Lee, and technical fellow Brian Jordan.

“Being recognized by the American Welding Society, a globally respected organization with over 70,000 members, is a tremendous honor,” said Lee. “This acknowledgment underscores the importance of our work in advancing additive manufacturing for critical aerospace applications.”

Tackling Cracking in High-Performance Alloys

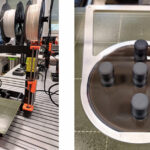

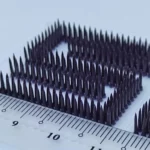

The team’s research explored the use of laser-blown powder direct energy deposition (Laser-powder DED), an additive manufacturing technique, to repair high γ’ IN-100 superalloy. This material, widely used in gas turbines for its ability to withstand high temperatures, is particularly prone to cracking during repairs, especially in the hot section of jet engines where combustion temperatures and pressures are at their peak.

Through a combination of advanced computer simulations and in-depth material analysis, ORNL researchers developed a method to significantly reduce cracking susceptibility. The study focused on controlling thermally induced residual stresses and optimizing preheat temperatures for the repair area.

Collaboration with Delta Airlines

Working in collaboration with Delta Airlines, the team demonstrated how these controlled conditions could improve the reliability and lifespan of IN-100 components.

“It was a significant challenge to simultaneously manage preheat temperature, manufacturing conditions, and thermally induced residual stresses,” Lee explained. The team’s efforts resulted in a dramatic reduction in cracking susceptibility, paving the way for safer and more durable repairs in high-performance applications.

The research was conducted at ORNL’s Manufacturing Demonstration Facility and was supported by the U.S. Department of Energy’s Advanced Manufacturing Office.

Expanding the Application of Additive Repairs

Lee expressed hope that the recognition for this work will lead to further developments in applying additive manufacturing for aerospace and other industries.

“We want to extend this approach to more complex geometries and real-world applications,” he said. “Our goal is to help improve the repair process for gas turbines and beyond.”

The research highlights ORNL’s commitment to addressing critical manufacturing challenges, contributing to advancements in additive manufacturing, and strengthening collaborations between government and industry.

Source: ornl.gov