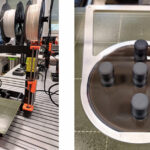

Infinity Turbine has introduced an innovative approach to electrode fabrication, combining fiber laser heat treating, additive manufacturing, and laser-induced carbonization. This new technology enables the transformation of carbon-rich materials, such as sugar and wood fibers, into hard carbon or graphene-like structures. The resulting 3D-printed electrodes are set to enhance the manufacturing process for Salgenx saltwater flow batteries, gas processing, and electrocatalyst applications.

Advancing Saltwater Flow Batteries with 3D-Printed Electrodes

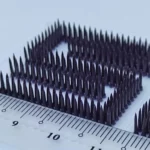

Salgenx saltwater flow batteries are known for their safe and environmentally friendly approach to grid-scale energy storage. Infinity Turbine’s introduction of 3D-printed carbon electrodes significantly boosts the battery’s performance by providing a high-conductivity, high-surface-area electrode structure. The combination of laser-induced graphene and customized 3D-printed geometries leads to faster ion exchange, improved energy density, and increased battery lifespan, all while using sustainable materials. Additionally, this manufacturing method reduces both production time and complexity through the use of just-in-time (JIT) technology, further lowering inventory costs.

The new electrode technology offers several advanced features that contribute to its efficiency. Infinity Turbine uses fiber lasers to induce carbonization in organic materials like sugar, transforming them into graphene-like carbon structures with excellent conductivity and structural integrity. This process takes place in a CO₂-flooded environment, which enhances carbonization efficiency by preventing combustion and ensuring high-purity carbon production. The 3D additive manufacturing process builds electrodes layer by layer, creating customized structures with improved surface area and mechanical strength, essential for enhancing energy storage. Furthermore, the technology integrates various battery materials quickly and efficiently through JIT manufacturing, allowing for the rapid development of components such as metallic powders and insulators. This combination of carbonization, 3D printing, and material flexibility enables the creation of highly efficient electrodes that meet the demands of energy storage and processing applications. The process can also incorporate mixed material layers, which are useful in gas processing and electrocatalysis applications.

These 3D-printed electrodes will greatly improve the performance of Salgenx saltwater batteries, which are already noted for their safety, cost-effectiveness, and environmental benefits. By enhancing battery charge times, energy density, and longevity, this new technology promises to deliver higher performance in renewable energy storage systems.

Expanding Research, Development, and Production Applications

The introduction of 3D-printed electrodes with selectable powdered materials opens new possibilities for research and development. It enables fast concept-to-reality materialization, streamlining product commercialization. The 3D fabrication process also paves the way for the development of machines dedicated to electrode and electrocatalyst production. This process could reshape manufacturing methodologies in a similar way to Tesla’s Gigapress, allowing for the creation of 3D-printed anodes and cathodes that form a complete electrolyzer cell.

Additional Applications: Gas Processing and Electrocatalysis

The versatility of Infinity Turbine’s 3D-printed carbon structures extends beyond energy storage. In gas processing, these carbon structures can be applied to in-situ processes, potentially enabling more efficient carbon capture and conversion systems. The high surface area and conductivity of the graphene-like materials are particularly beneficial for these applications, including electro-desalination systems that convert seawater into fresh water.

The 3D build concept is also well-suited for electrocatalyst applications. Infinity Turbine’s system can integrate advanced electrocatalyst technology, facilitating the conversion of CO₂ and water into valuable carbon-based products such as methylglyoxal (C3) and 2,3-furandiol (C4) with over 99% efficiency. These materials hold significant promise for sustainable manufacturing, offering non-toxic alternatives for industrial products like plastics and adhesives, where methylglyoxal could replace formaldehyde.

A Breakthrough in Energy Solutions

Infinity Turbine’s development of 3D-printed carbon electrodes marks a significant leap forward in energy storage and electrocatalyst technology. These carbon-based materials are set to enhance the efficiency of Salgenx saltwater batteries and transform gas processing applications. By utilizing sustainable organic materials such as sugar and wood fibers, Infinity Turbine underscores its commitment to environmentally friendly manufacturing and clean energy innovation.