Senior Airman Devon Word from the U.S. Air Force’s 48th Munitions Squadron has developed a 3D-printed insert to address a longstanding issue with 20 mm ammunition jamming during the loading process. The innovation, used at RAF Lakenheath, U.K., enhances the operation of the Universal Ammunition Loading System (UALS) by resolving a design flaw in the replenisher table, where rounds would frequently jam, causing delays and risking injury.

A Simple Solution to a Complex Problem

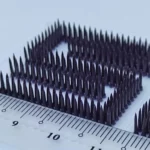

The jamming issue, caused by a gap in the ammunition loader, required manual troubleshooting that could take up to 15 minutes per occurrence, adding up to 798 man-hours annually. Word’s specially designed 3D-printed insert fills this gap, allowing smoother operations and eliminating the need for constant intervention. The U.S. Air Force estimated that this simple yet effective design could save over 750 man-hours annually for the 48th Fighter Wing.

Collaborative Innovation and 3D Printing at Work

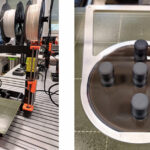

Word worked alongside Staff Sgt. Bethany Levi, part of the Air Force Repair Enhancement Program, to conceptualize and design the 3D-printed insert using graphic modeling software. Over six trials were conducted with 11 prototypes before finalizing the design. The insert is manufactured using a Stratasys F900 3D printer and has now become a regular part of operations, proving its value in reducing machine malfunctions and improving efficiency.

This innovation is a prime example of how personnel-led ideas can enhance logistical operations and improve equipment functionality. “Airmen working directly with equipment and processes often have unique insights into operational challenges and potential improvements,” said Lt. Col. Jonathan Tolman, 48th MUNS commander, praising Word’s effort to address a common issue.

The Role of Additive Manufacturing in Defense

This effort also highlights the growing role of additive manufacturing in defense applications. The use of 3D printing in the military is expanding rapidly, with applications ranging from small-scale inserts like Word’s innovation to larger parts for systems such as the M61 Vulcan Gatling gun used across U.S. Air Force platforms like the F-15 and F-22.

Additive manufacturing is becoming an essential tool for the U.S. military, helping to reduce downtime, improve readiness, and offer on-demand production capabilities for critical equipment. Word’s innovation joins a growing list of 3D-printed solutions being used in military operations, from ammunition loaders to aircraft repairs.

Looking Toward the Future

With its success at RAF Lakenheath, the 3D-printed insert is now undergoing patenting and will be shared with other U.S. Air Force munitions squadrons. This grassroots innovation is expected to have a significant impact on ammunition handling and overall operational efficiency across the service.

As the U.S. military continues to embrace 3D printing, the potential for rapid prototyping, faster repairs, and more cost-effective solutions continues to grow. From small inserts to major system components, additive manufacturing is poised to change the way the military approaches equipment maintenance and innovation.

Source: theaviationist.com