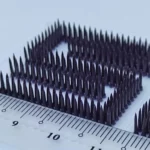

Shanghai Hanbang 3D Tech Co, Ltd (HBD) has announced a significant advancement in the production of turbine blades using additive manufacturing. In a recent study, HBD successfully reduced the required support structures for impeller manufacturing by 96%, lowering the unsupported angles from the typical 45° to an impressive 6°.

Advancing Turbine Blade Production

HBD’s breakthrough centers on minimizing the internal support structures during the printing process of turbine blades. By employing only essential support structures designed for easy removal, the company dramatically reduced the challenges associated with support structure removal, significantly cutting down the time required for the entire manufacturing process.

The company explained that support structures play a crucial role in maintaining the stability of manufactured parts, particularly by preventing deformation due to thermal stresses, facilitating heat transfer, and protecting the part from potential damage by the recoater blade. Additionally, support structures help secure the part during the build process to ensure stability. However, traditional metal additive manufacturing machines generally restrict unsupported overhanging features to angles of 35-45°. The addition of each support structure not only increases manufacturing time and material costs but also necessitates time-consuming post-processing for removal, ultimately decreasing productivity.

Technological Innovations for Reduced Support Structures

To achieve this remarkable reduction in support structures, HBD implemented several technological innovations. These advancements included optimizing algorithms for support structures, implementing real-time control of melt pool temperature, enhancing powder deposition techniques, and developing metal alloy materials specifically designed for unsupported additive manufacturing.

While completely eliminating support structures in metal additive manufacturing remains a challenge, industry leaders, including HBD, are actively researching and developing technologies aimed at reducing or eliminating the need for supports. HBD has expressed its commitment to further explore unsupported and minimally supported manufacturing technologies, with the goal of providing more efficient and reliable metal additive manufacturing solutions to its clients. This effort also aims to expand the potential applications of additive manufacturing in industrial production.

HBD’s recent breakthrough in turbine blade production marks a significant step forward in the field of metal additive manufacturing. By drastically reducing the need for support structures, HBD is not only improving efficiency and reducing costs but also paving the way for broader industrial applications. As the company continues to refine its technologies, the possibilities for unsupported and less supported additive manufacturing are set to expand, offering more versatile and innovative solutions for the manufacturing industry.

Source: metal-am.com